Significant advances in electrolysis within HYPRAEL project thanks to the collaboration of Fraunhofer IWS, Fraunhofer IFAM and VECO PRECISION

The HYPRAEL project has achieved important milestones in the development of advanced electrolysis technologies, thanks to strong collaboration between its partners Fraunhofer IWS, Fraunhofer IFAM and VECO PRECISION. These advances promise to significantly improve the efficiency and durability of electrolysers, bringing green hydrogen production closer to a viable industrial scale.

Innovation in substrates and electrodes:

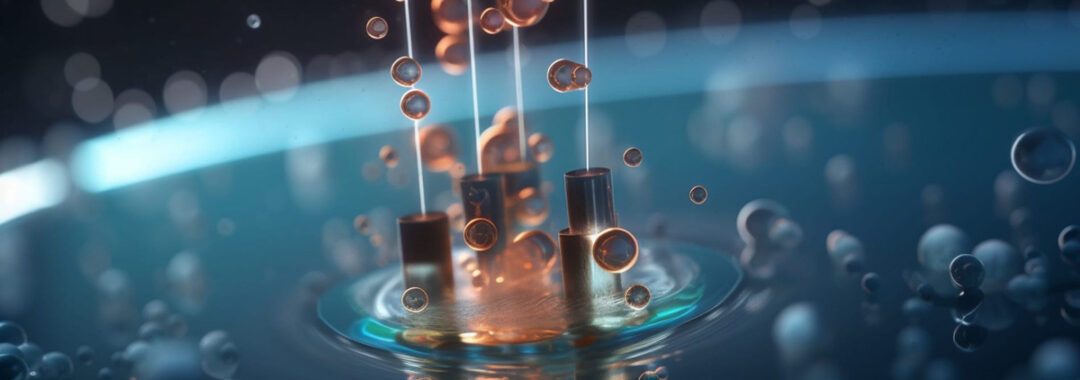

VECO PRECISION has led the development of an innovative 3D structured substrate and electrode. The new substrate facilitates electrolyte delivery and gas bubble removal, crucial for operating at high current densities and temperatures. Validation by Computational fluid dynamic (CFD) simulation has confirmed the effectiveness of this design. The 3D electrode, optimised through simulation and extensive testing, has been shown to significantly reduce the cell potential in hydrogen evolution reactions (HER) and oxygen evolution reactions (OER), outperforming the expanded Ni grid.

Development of efficient and durable catalysts:

Fraunhofer IFAM has focused its efforts on the development of long-lasting catalysts for HER and OER. A specially designed test rig has made it possible to analyse the behaviour of various materials under extreme conditions (temperatures up to 120°C and KOH concentrations of 1-45 wt%.) The results show an increase in electrode activity with temperature, albeit with a limit at 100°C, and lower activity at high KOH concentrations due to decreased conductivity and increased viscosity.

Optimisation of DSE production by APS:

Fraunhofer IWS has established a manufacturing process to coat the Veco Pin substrate with corrosion-resistant and HER- and OER-active species. Optimisation of the atmospheric plasma spraying (APS) process has made it possible to produce homogeneous catalyst coatings on spacers up to 130 mm in diameter. Different Ni and NiAl-based materials have been tested, achieving defect-free coating adhesion and high layer homogeneity.

Contact us for more information about the Electrolysis advances!