In European laboratories, driving high pressure green hydrogen production, where steel pipes intertwine like arteries and steam sketches invisible maps in the air, teams of engineers are driven by a shared obsession: to free hydrogen — as much as possible — from its dependence on mechanical compressors. Learn more about the project’s foundations on the .

This isn’t science fiction. It’s HYPRAEL, a project that sounds futuristic but is being built, quite literally, with hands in the present. Its goal is as bold as it is concrete: to produce green hydrogen directly at pressures beyond today’s state of the art, drastically reducing the need for mechanical compression afterward.

When the challenge is invisible, but heavy: compression

Today, producing hydrogen isn’t the main issue. The real challenge comes next. To store or transport it, it must be compressed. And that costs energy, money, and time. HYPRAEL aims to skip that step — or at least, make it much smaller.

The alkaline alchemy

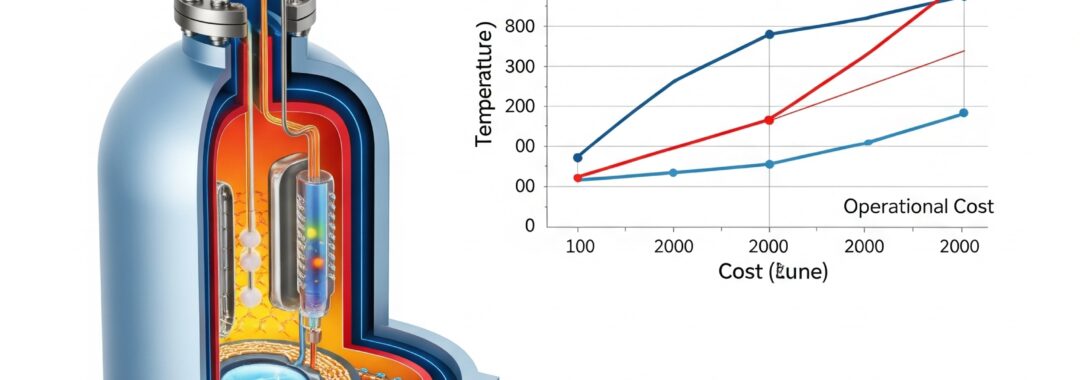

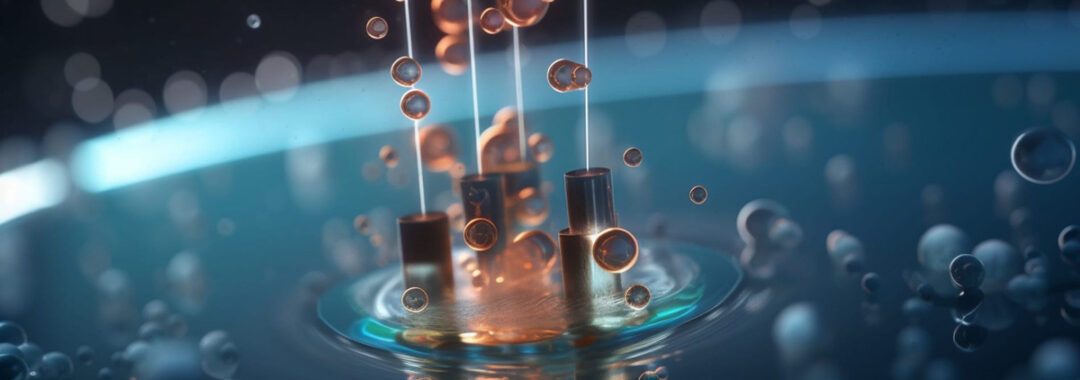

The chosen technology isn’t new, but the ambition behind it is. Alkaline electrolysis has been used for decades, but it has never been pushed this far: to operate above 30 bar, to explore its limits and aim for 50 or even 80 bar of pressure, while also improving efficiency at higher temperatures — with advanced, sustainable materials and minimal loss in performance. It’s like asking a bicycle to compete with a bullet train… and win. Discover the full scope of the initiative through its listing on .

But the researchers aren’t intimidated. They’re redesigning cells, testing new electrodes and separators, and fine-tuning each parameter like a symphony. Because they know that if this works, it could change the rules of the game.

Beyond the lab

HYPRAEL doesn’t stop at academic papers. It’s grounded and focused on the industry. The project will validate prototypes under real-world conditions, measure environmental and economic impact, and work toward a future where Europe not only consumes green hydrogen — but produces it with homegrown technology. Read how the is coordinating this European effort. View the project details on the .

A European effort, built together HYPRAEL is not a solo endeavor — it’s powered by a consortium of leading institutions and companies across Europe. Coordinated by the Aragon Hydrogen Foundation, the project brings together key players such as Fraunhofer, Green Hydrogen System, AGFA, VECO, and Syensqo. Each partner contributes its expertise: from advanced materials and cell design to industrial validation and process engineering. This collective effort ensures that HYPRAEL’s innovations are not only technically sound, but scalable, sustainable, and aligned with Europe’s vision for clean hydrogen production.