3D Electrodes for Green Hydrogen: Veco Revolutionizes Alkaline Electrolysis

New electroforming technology reduces costs and increases efficiency in green hydrogen production | Renewable energy innovation

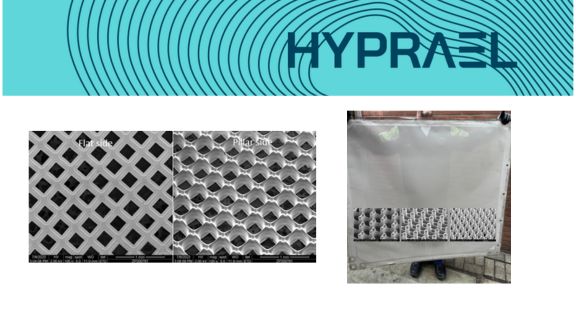

Veco together with Fraunhofer have developed 3D structured electrodes that promise to transform the green hydrogen industry through high-efficiency water electrolysis, a key technology for energy decarbonization in Spain and Europe.

High-efficiency electrodes: The key to competitive green hydrogen

Veco’s new electrodes for alkaline electrolyzers incorporate 3D electroforming technology that significantly improves the performance of HER (hydrogen evolution reaction) and OER (oxygen evolution reaction), fundamental processes in renewable hydrogen production.

Electroforming technology: plug & play solution

Electroforming technology allows customization of:

- Electrode thickness

- Specific geometries and structures

- Shape adapted to each cell design

This customization eliminates post-treatment stages, reduces assembly costs, and facilitates direct integration into industrial electrolysis systems.

CFD simulation: Digital optimization for clean energy

The development employed CFD simulation (computational fluid dynamics) to design the optimal structure that maximizes:

- Efficient gas bubble release

- Optimized electrolyte flow

- Enhanced electrocatalytic activity

Validated performance: Results in alkaline electrolyzers

Tests with alkaline electrolyzers (30% KOH, 40°C, Zirfon membrane) demonstrated that NiE3 electrodes significantly outperform traditional expanded nickel meshes:

✓ Notable reduction in cell potential

✓ Higher efficiency at high current densities

✓ Ideal for high-performance systems

Applications in energy transition

This innovation positions high-performance electrolyzers as a viable solution for:

- Industrial green hydrogen production

- Renewable energy storage

- Transport and industry decarbonization

- Compliance with European Net Zero targets

Impact on the renewable hydrogen market

With Spain positioning itself as a European green hydrogen hub, these technological improvements in alkaline electrolysis reduce the CAPEX and OPEX of electrolyzers, bringing renewable hydrogen closer to competitiveness against fossil fuels.

The combination of increased electrocatalytic activity and improved bubble release positions this technology as a promising breakthrough for making hydrogen production through electrolysis more efficient and economical.

The HYPRAEL project has received funding from the Clean Hydrogen Partnership under Grant Agreement No 101101452. This Partnership receives support from the European Union’s Horizon Europe Research and Innovation program, Hydrogen Europe and Hydrogen Europe Research.