Agfa-Gevaert’s role in the hydrogen economy

Green hydrogen is becoming a key driver for decarbonizing industry, particularly in sectors that are difficult to electrify such as ammonia, steel, and petrochemicals. Of the available production technologies, alkaline electrolysis is widely recognized for its scalability and favorable cost structure. Within this landscape, Agfa-Gevaert supports the transition to green hydrogen by supplying Zirfon membranes, which are an essential component of alkaline water electrolyzers.

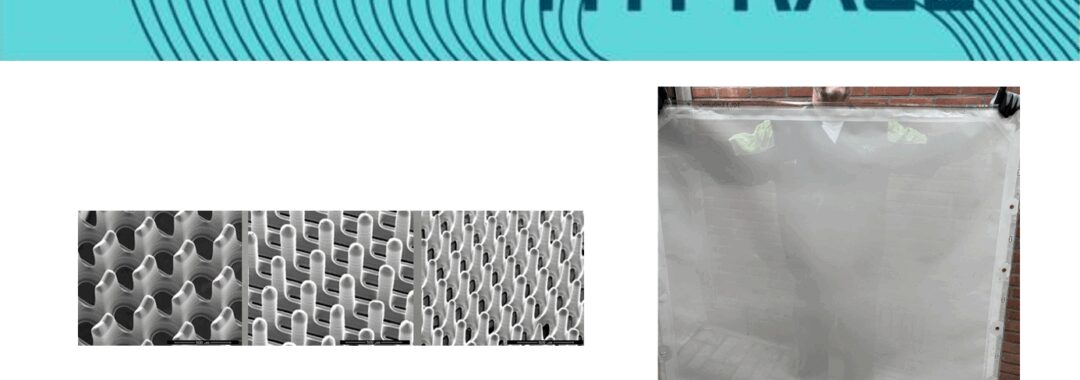

Figure 1: The ZIRFON™ prototype diaphragm, developed within HYPRAEL.

Membranes in alkaline electrolysis, how does it work?

The membrane is a core element of an alkaline electrolyzer. It physically separates the cathode and anode, preventing hydrogen and oxygen from mixing and thereby avoiding the formation of explosive gas combinations. At the same time, the membrane must enable efficient ion transport, which is crucial for maintaining high performance and overall system efficiency.

Why Zirfon? Safe, scalable and proven

Zirfon membranes are designed for safe and dependable operation, including in systems powered by variable renewable energy sources. More than 4 GW of Zirfon membranes have been supplied worldwide, with no safety incidents reported over more than 15 years of industrial operation. This proven track record demonstrates the maturity of the technology. By integrating Zirfon membranes, customers can reduce the cost per kilogram of green hydrogen by more than 50 percent, improving the economic feasibility of projects in a market that still faces high costs and supply chain challenges. In September 2025, Agfa-Gevaert will open the world’s largest alkaline membrane production facility, supported by an €11 million EU Innovation Fund grant. The facility will have an annual capacity of 1 million m² of Zirfon membranes to meet increasing global demand.

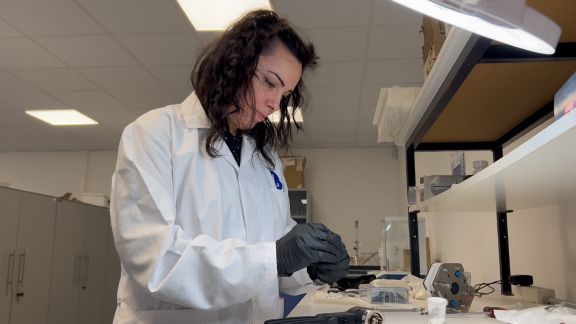

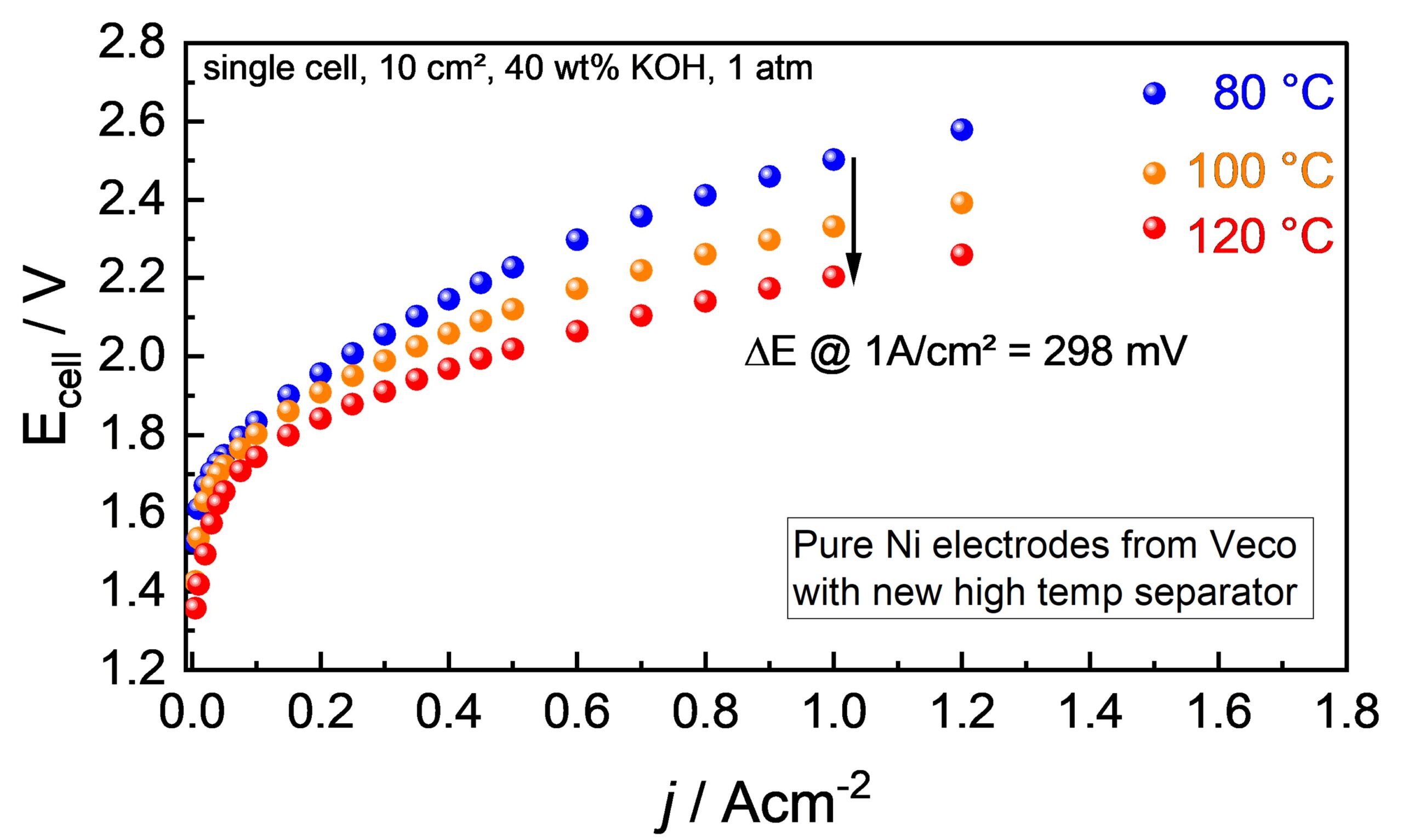

Figure 2: Electrochemical testing by Fraunhofer on new prototype diaphragm.

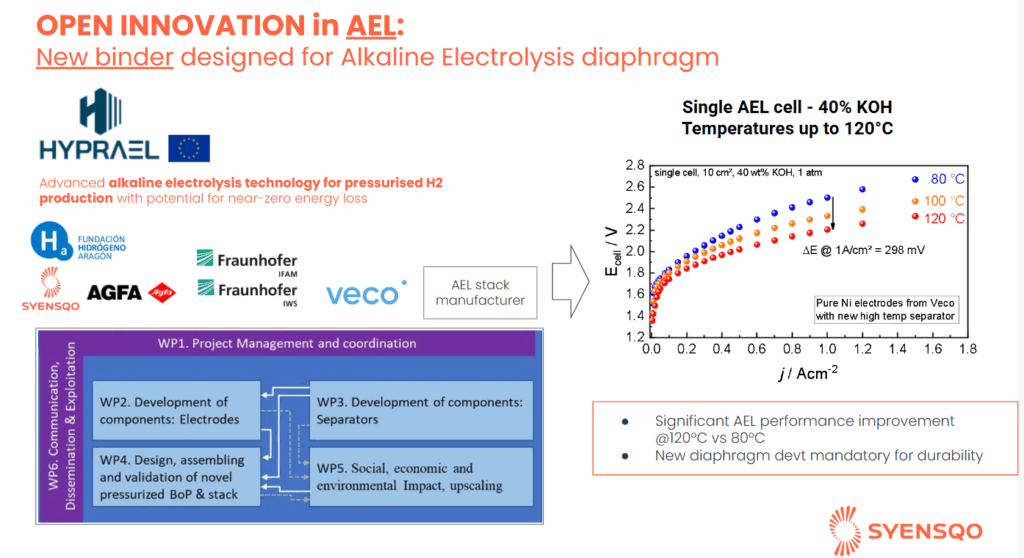

Innovation within HYPRAEL

In HYPRAEL, we are developing separators for operation at elevated temperatures and pressures, specifically 120°C instead of 90°C, and up to 50 bar as a means of pushing electrolyzer efficiency further than previously possible. Together with Syensqo, Agfa has developed a new diaphragm that can withstand these demanding conditions. Electrochemical performances of this new diaphragm were confirmed thanks to an AEL single cell prototype developed by our partner Fraunhofer IFAM, Dresden. Research carried out by Syensqo provided access to a next-generation polymer enabling the development of a diaphragm with unprecedented performance in harsh environments inside alkaline water electrolyzers. This work positions HYPRAEL at the forefront of innovation for next-generation high-performance alkaline electrolysis systems.

Collaborating for Excellence Learn more about the world-class partners making HYPRAEL possible. Explore our Partners & Consortium →

You might also be interested in: